FRS-1000 Product Features

The company has been committed to the research of waterproof coatings and sealants for decades, and the waterproof life of silicone elastic waterproof coatings is more than 15 years.

Silane modified polyether waterproof coating is a product specially designed for building waterproofing. It is solvent-free, green and environmentally friendly, with extremely low VOC content. It has no irritating odor during use and solidifies by reacting with moisture to form a seamless elastic waterproof membrane. It has excellent corrosion resistance, bonding properties, and good compatibility with other materials. Its waterproof effect is more durable than traditional polyurethane coatings.

FRS-1000 Product Parameters

| Application Method | Spraying, rolling, brushing |

| State | Liquid Coating |

| Model Number | FRS-1000 |

| Product Name | Silane Modified Polyether Waterproof Coating |

| Color | White; Gray; Customized |

| Feature | UV resistance, Good weather resistance;Environmentally friendly |

| Type | Waterproof coating |

| Use | ①Suitable for use with TPO membrane; ②Widely used for roofing, building underground, building roof waterproofing, and indoor bathroom waterproofing. |

| Shelf Life | 10 months |

| Certificate | T/CBMF105-2021 T/CWA203-2021 |

| Packing | 20 KG |

| Selling Units | KG |

| Single Package Size | 14*7*20 cm |

| Single Gross Weight | 0.550 KG |

| MOQ | 700 KG |

FRS-1000 Product Application Scenarios

①Suitable for use with TPO membrane;

②Widely used for roofing, building underground, building roof waterproofing, and indoor bathroom waterproofing.

FRS-1000 Product User Guide

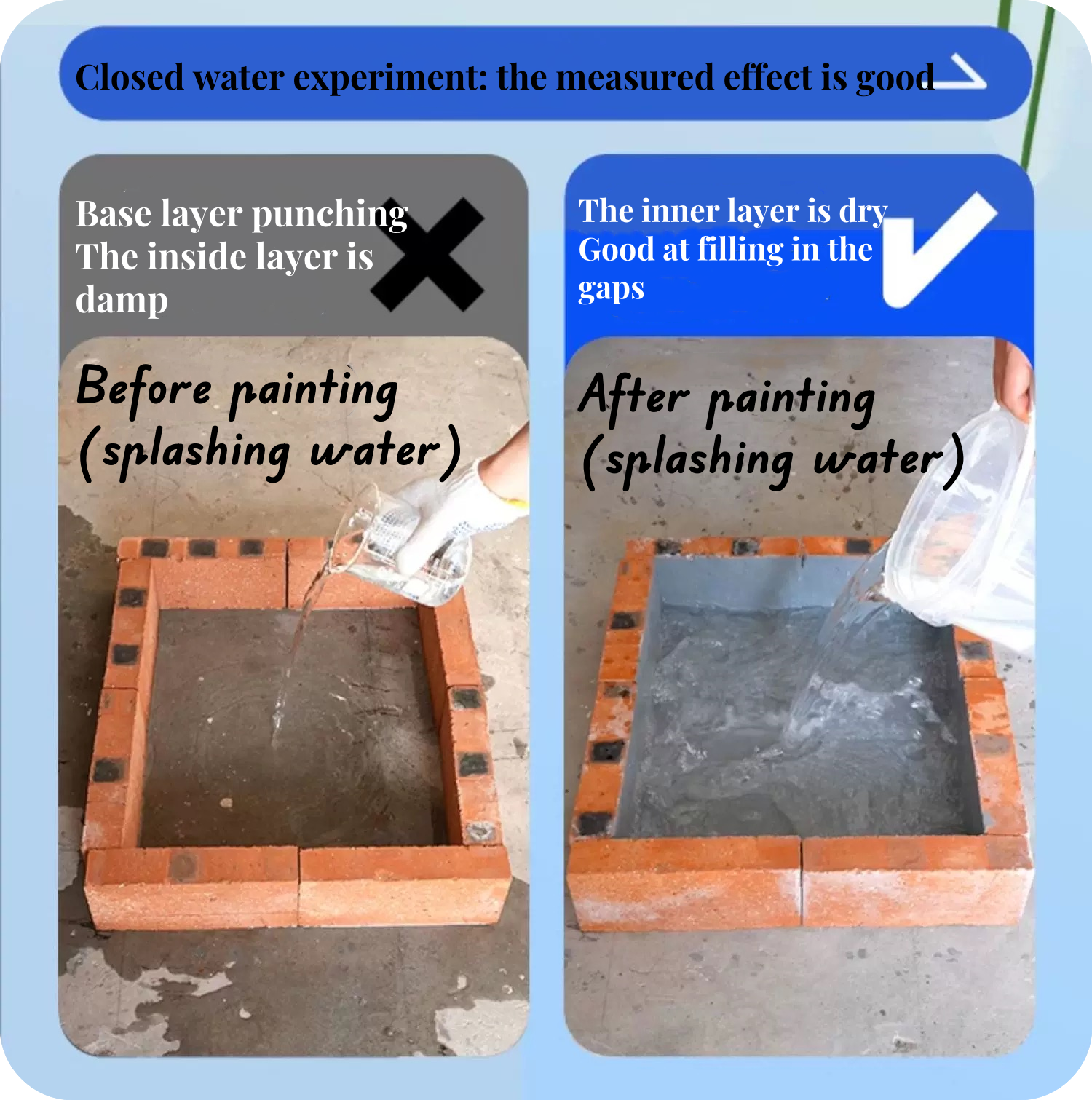

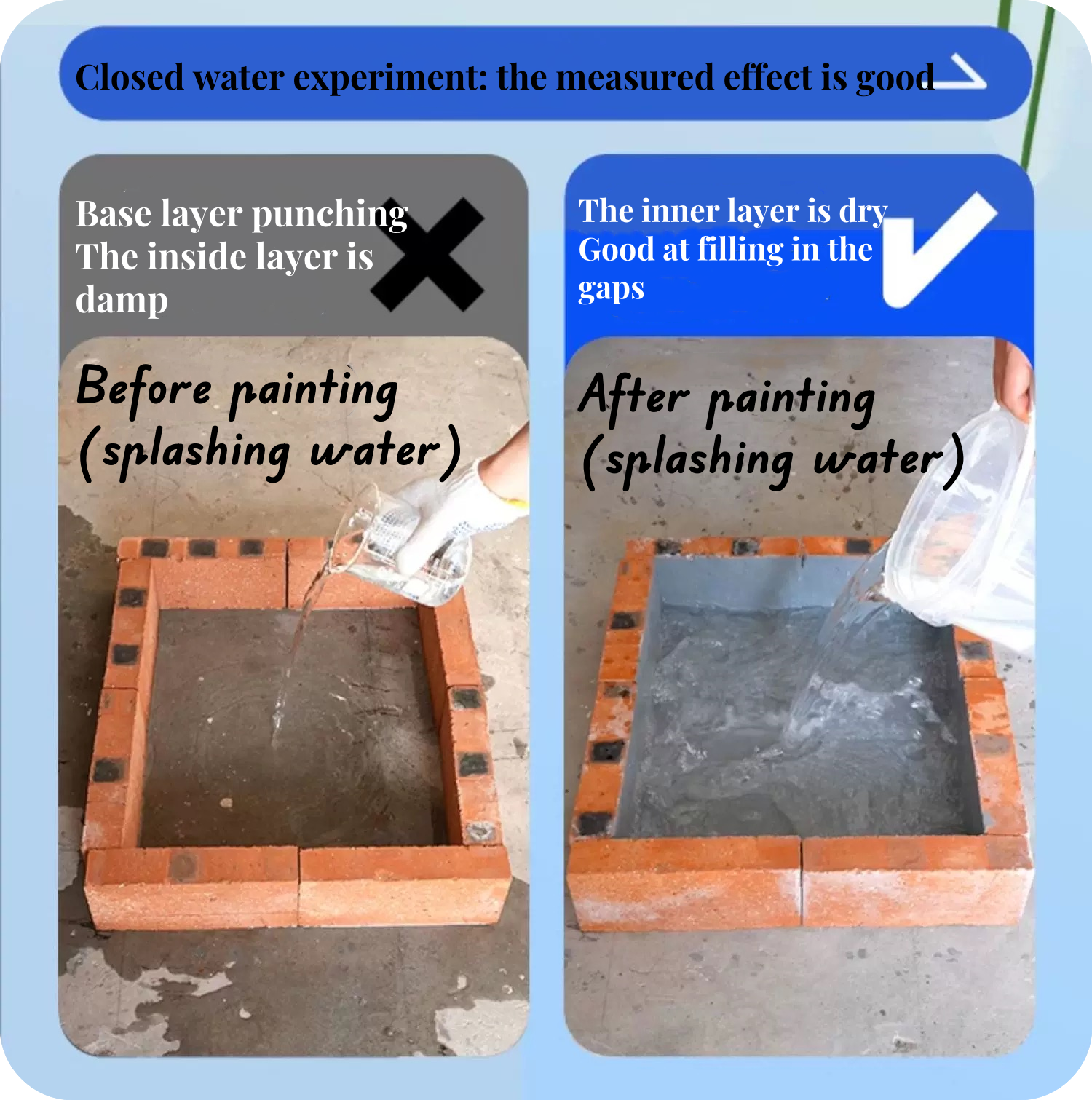

① Base layer treatment: The surface of the base layer must be clean and solid, and no sand, floating dust, etc. are allowed;

②Seam treatment: If there are cracks of more than 3mm on the surface, MS sealant should be filled, and then the coating should be applied after the glue dries;

③Construction method: If you need to add thinner before using the paint, the ratio of paint to thinner is 10:4. The construction can be carried out by scraping, rolling or spraying. Generally, it is applied twice. The total thickness of the coating film is 0.8-1mm. The coating interval is 4-12 hours, depending on the ambient temperature;

④The recommended dosage is greater than 1.5-1.6kg/㎡.

FRS-1000 Product Details