FRS-200 Product Features

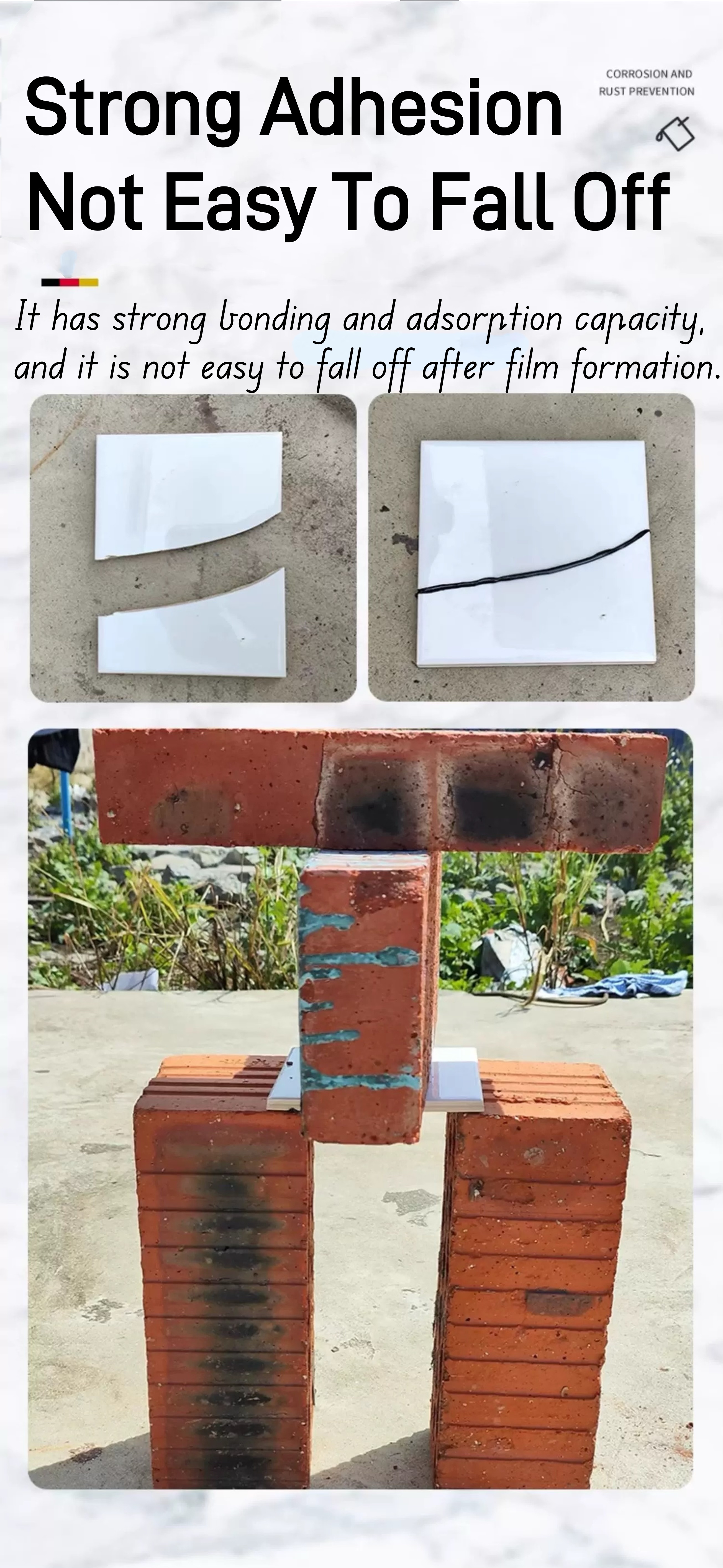

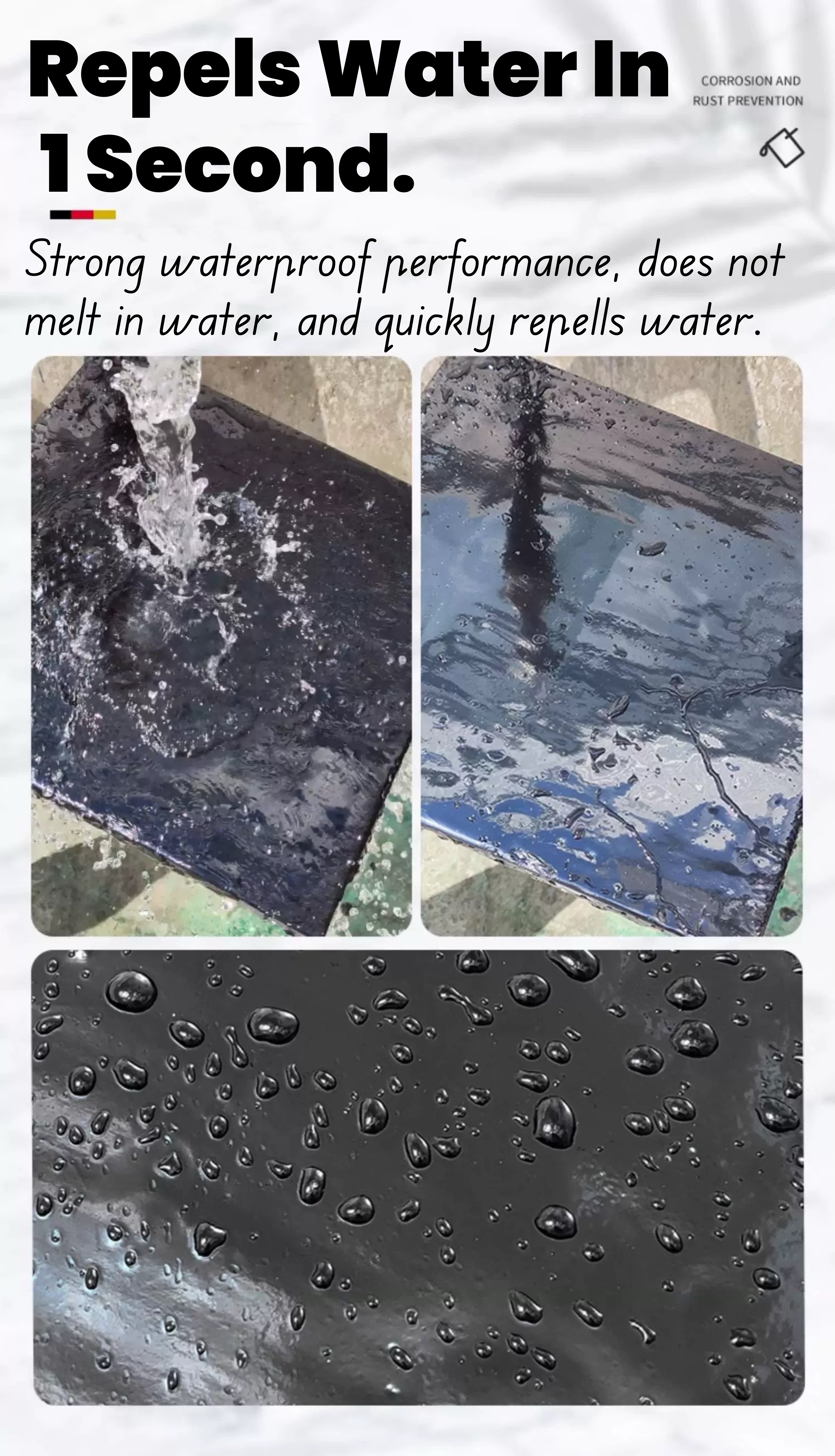

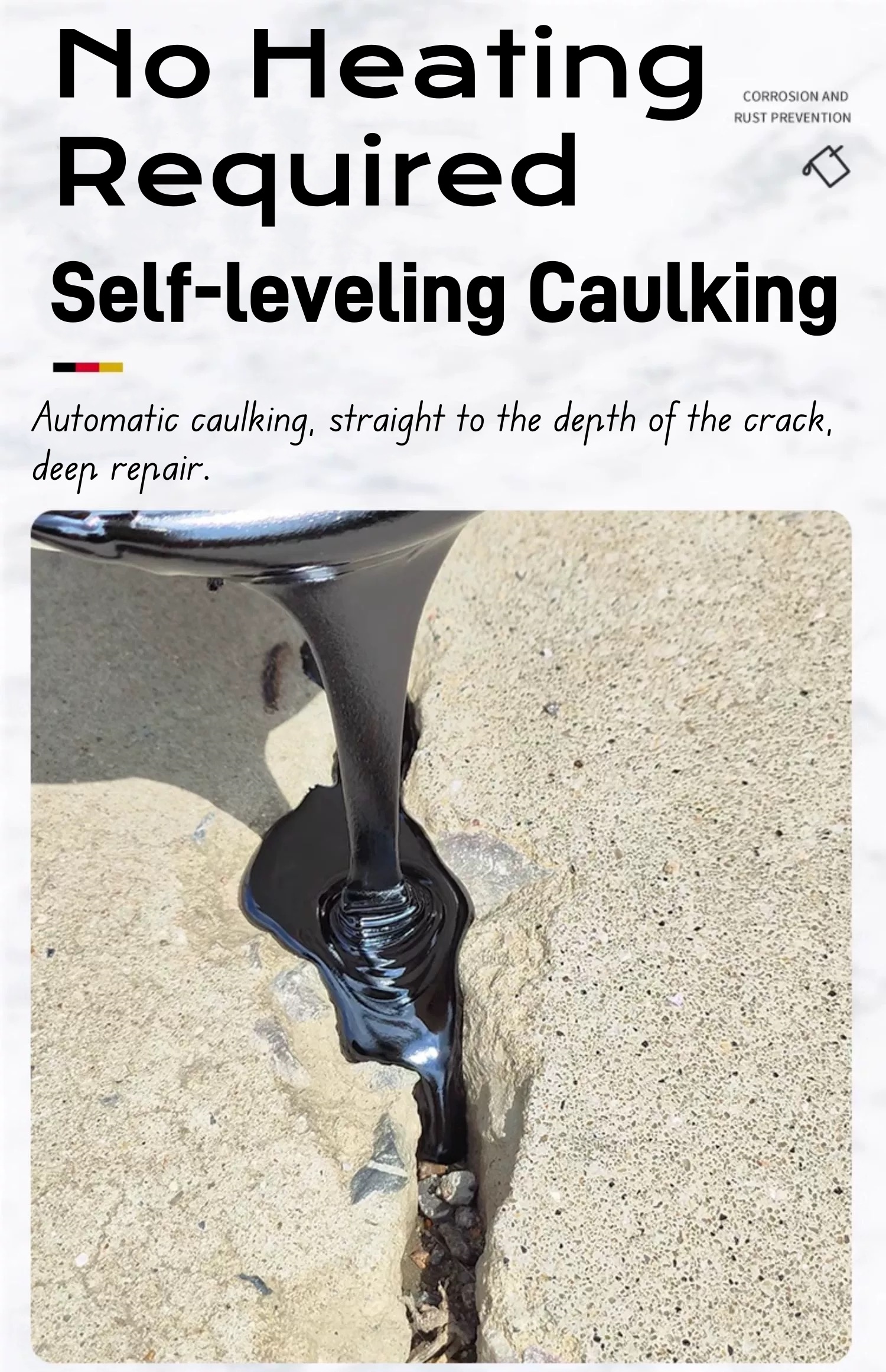

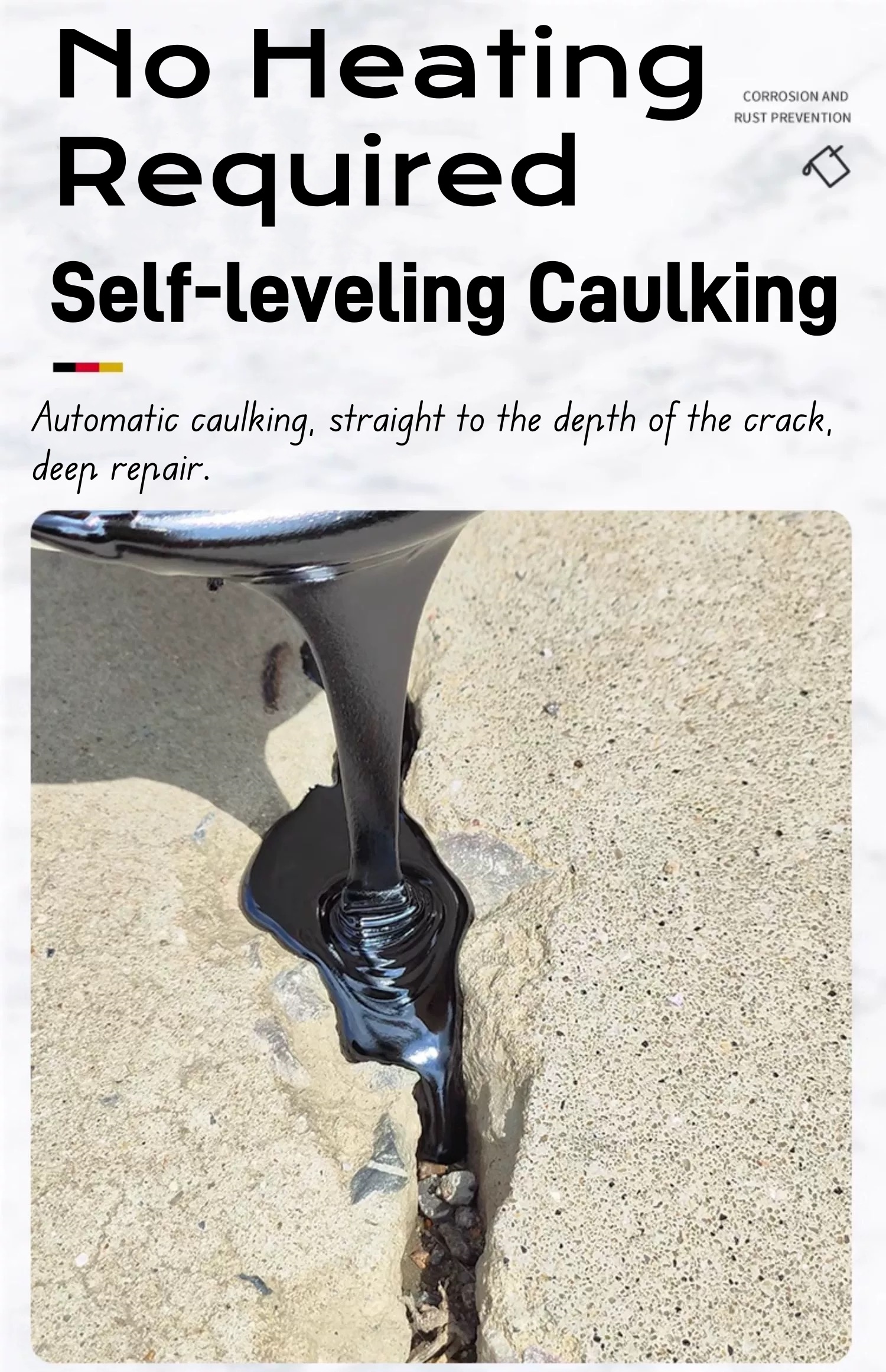

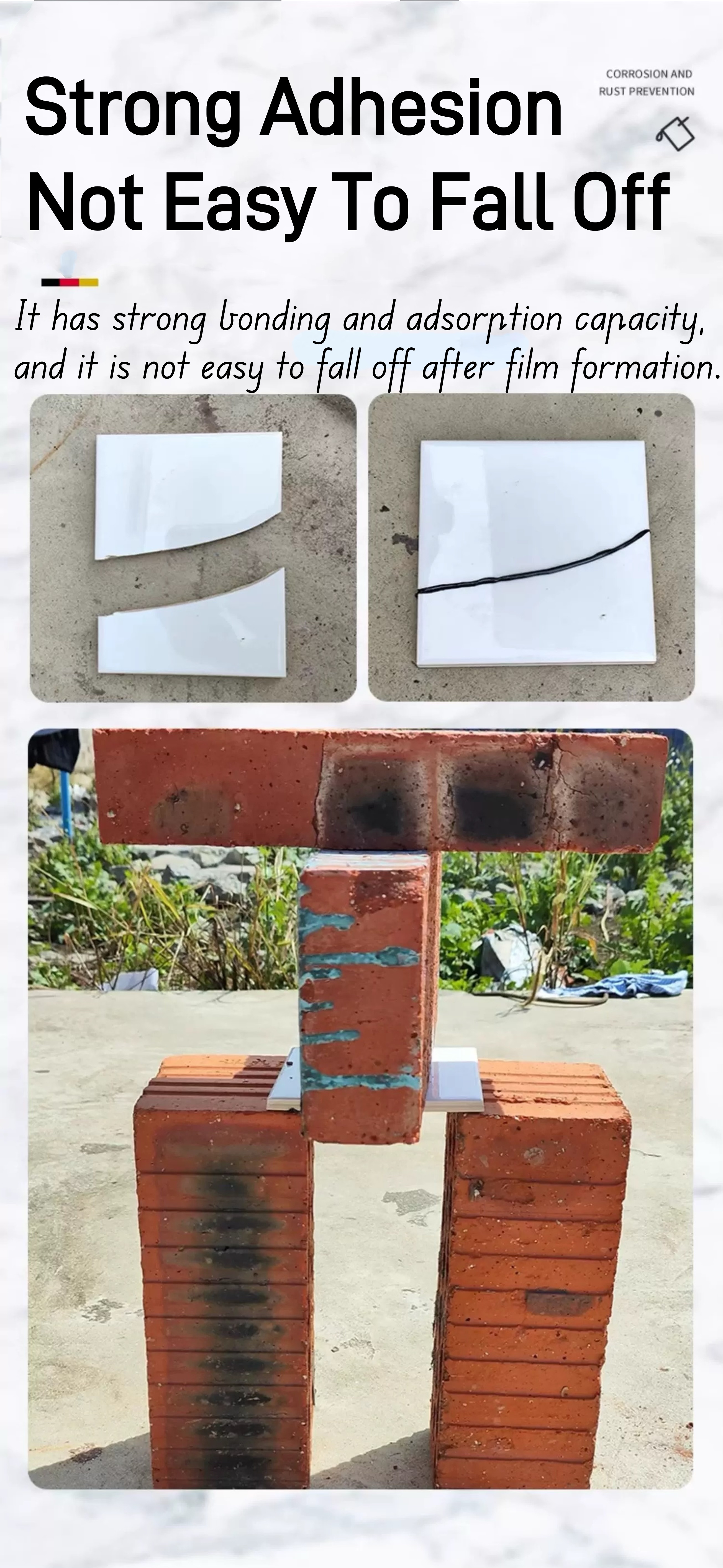

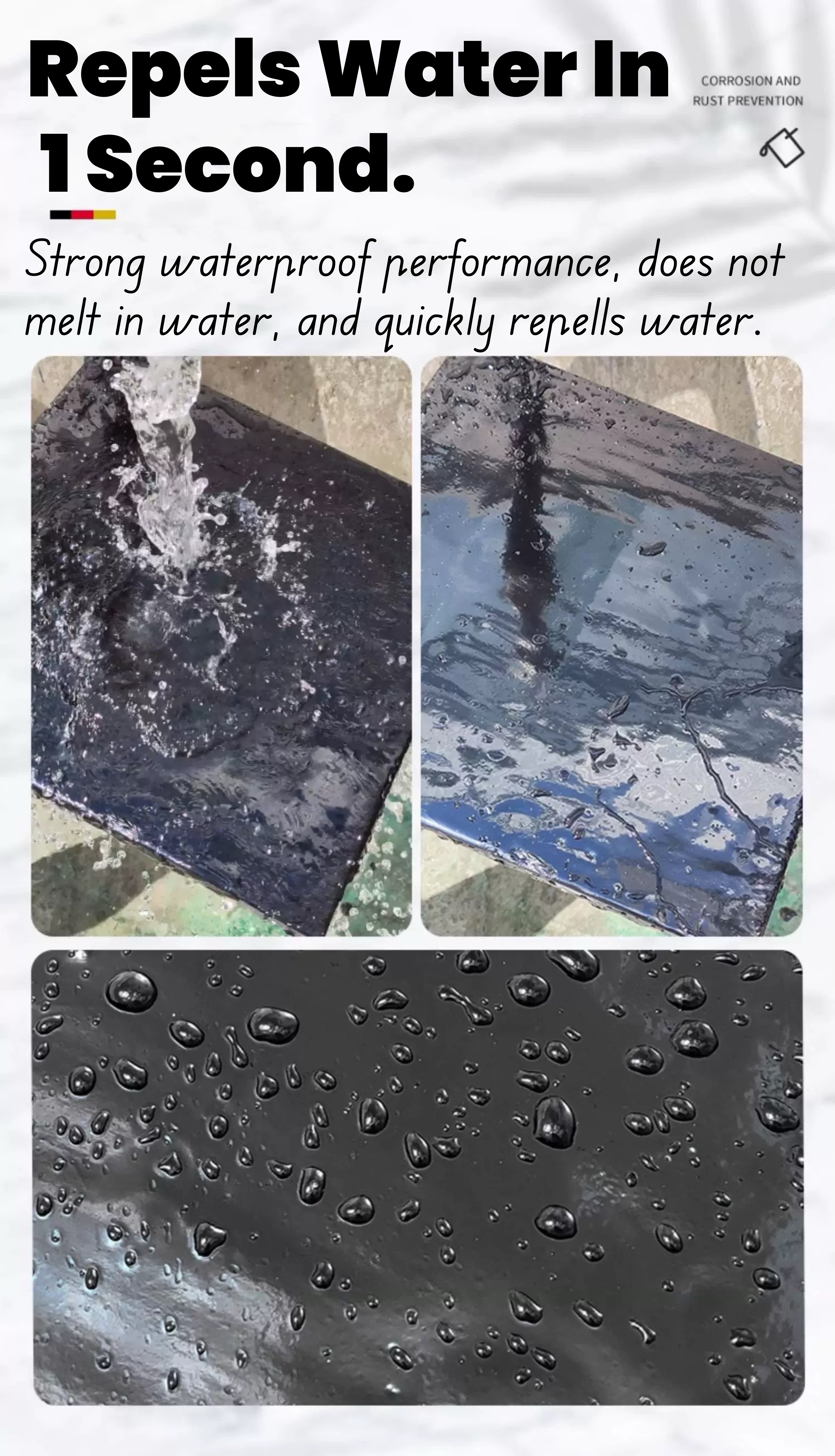

A new type of caulking agent specially developed for airport runways and roads. It has strong adhesion, simple construction, and stress relief. Relying on strong elasticity, it will elastically deform as the crack expands and contracts, and will always maintain its sealing effect. It can be constructed at room temperature. It will not deform, crack or pulverize when cured at high temperatures outdoors. It will not affect elasticity at low temperatures of -80°C.

FRS-200 Product Parameters

| Application Method | Use with glue gun |

| State | Paste sealant |

| Model Number | FRS-200 |

| Product Name | Silicone Road Caulking Sealant |

| Color | Gray; Black; Customized |

| Feature | Self-leveling, stress relief, high and low temperature resistance and extrusion resistance. |

| Type | Silicone sealant |

| Use | ① Can be used for sealing and repairing horizontal, vertical, and irregular cracks and joints; ② Suitable for repairing cracks in concrete road expansion joints, airport runways, building roof waterproofing, basement and bathroom waterproofing, water conservancy projects, etc. |

| Shelf Life | 10 months |

| Certificate | JC/T 976-2005 |

| Packing | 450g hard support/750g hose/5kg barrel (built-in vacuum foil bag)/customized |

| Selling Units | KG |

| Single Package Size | 14*7*20cm |

| Single Gross Weight | 450g/750g/5kg |

| MOQ | 700kg

|

FRS-200 Product Application Scenarios

① Can be used for sealing and repairing horizontal, vertical, and irregular cracks and joints;

② Suitable for repairing cracks in concrete road expansion joints, airport runways, building roof waterproofing, basement and bathroom waterproofing, water conservancy projects, etc.

FRS-200 Product User Guide

①Clean the construction surface to ensure it is dry, free of oil and dust;

② Cut the mouth of the bottle, install the glue nozzle, cut the glue nozzle according to the required size, and squeeze it out with a glue gun;

③ The squeezing action of sealant should be carried out continuously to make the glue evenly squeezed out and move evenly and slowly to ensure that the joint is filled with sealant. It is necessary to prevent the nozzle from moving too fast and causing bubbles or cavities;

④ Carry out surface smoothing and modification within the surface drying time.

FRS-200 Product Details