FRS-109 Product Features

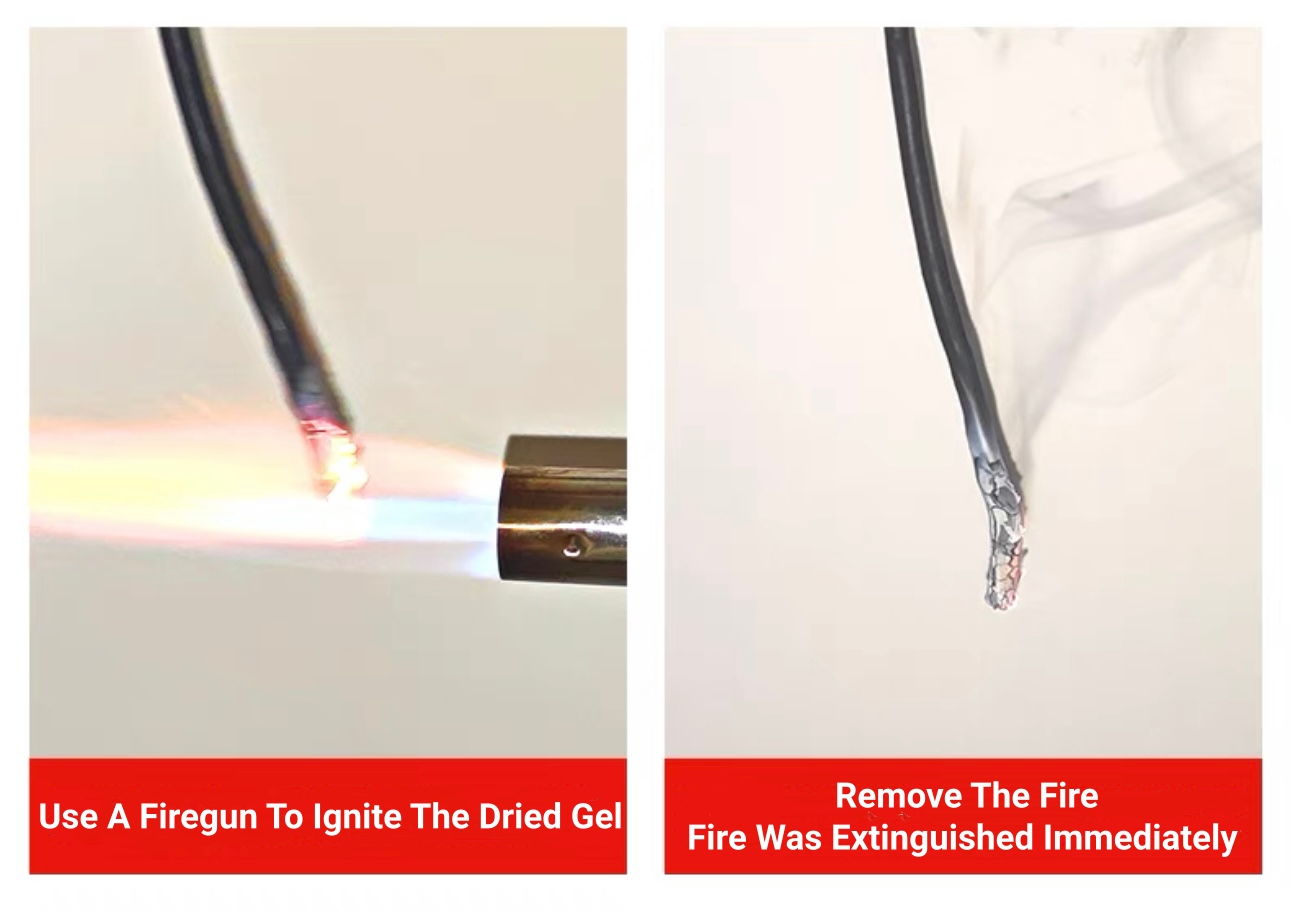

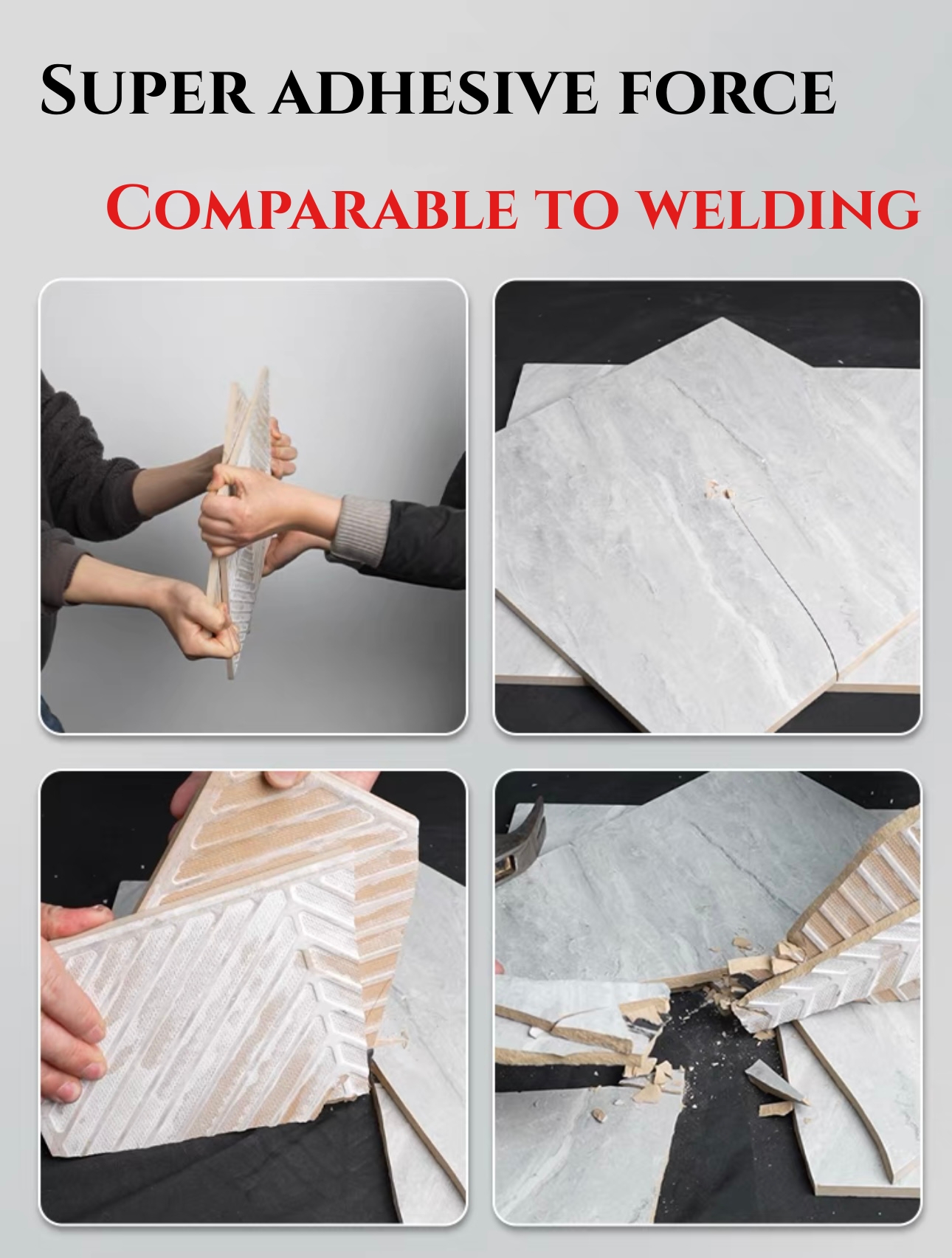

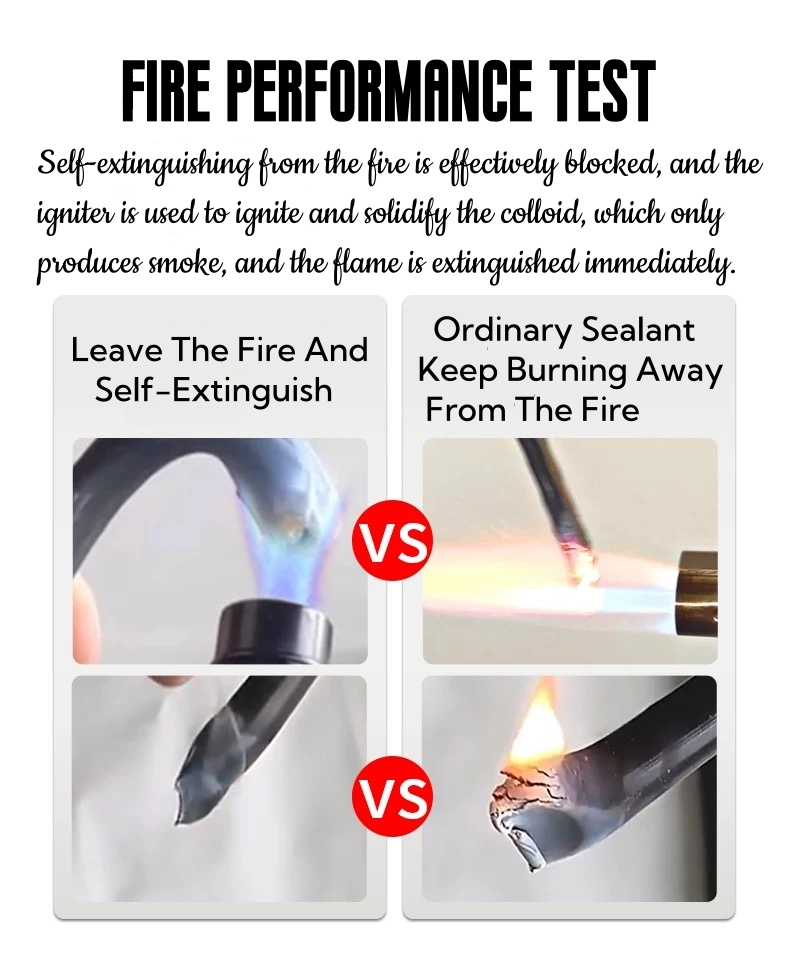

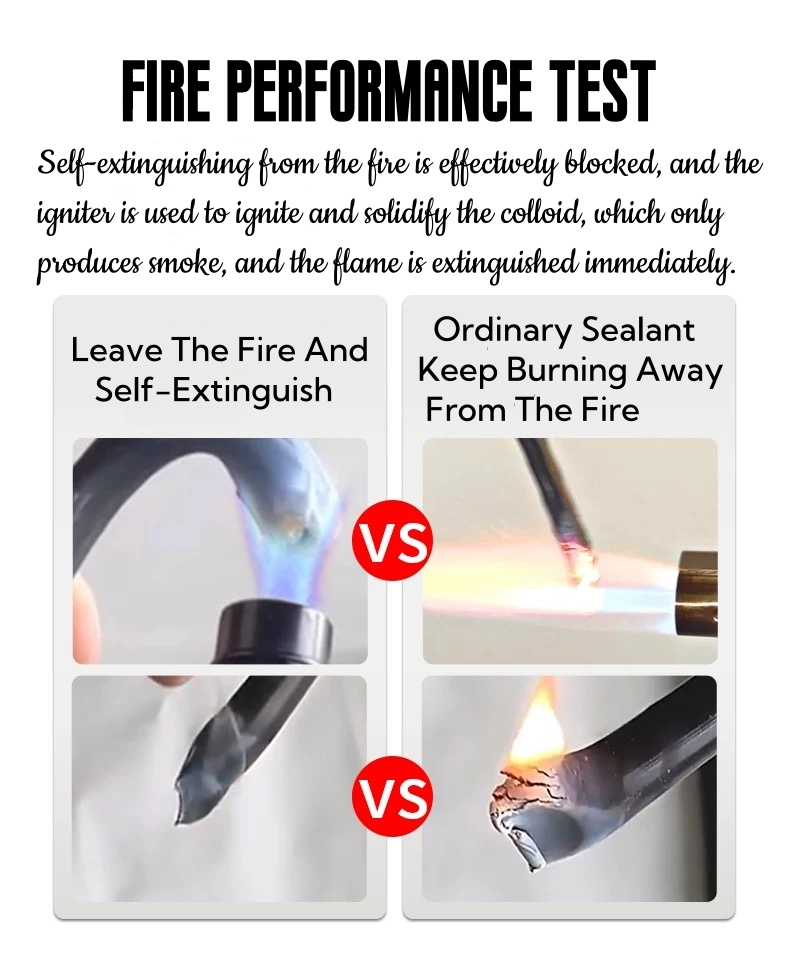

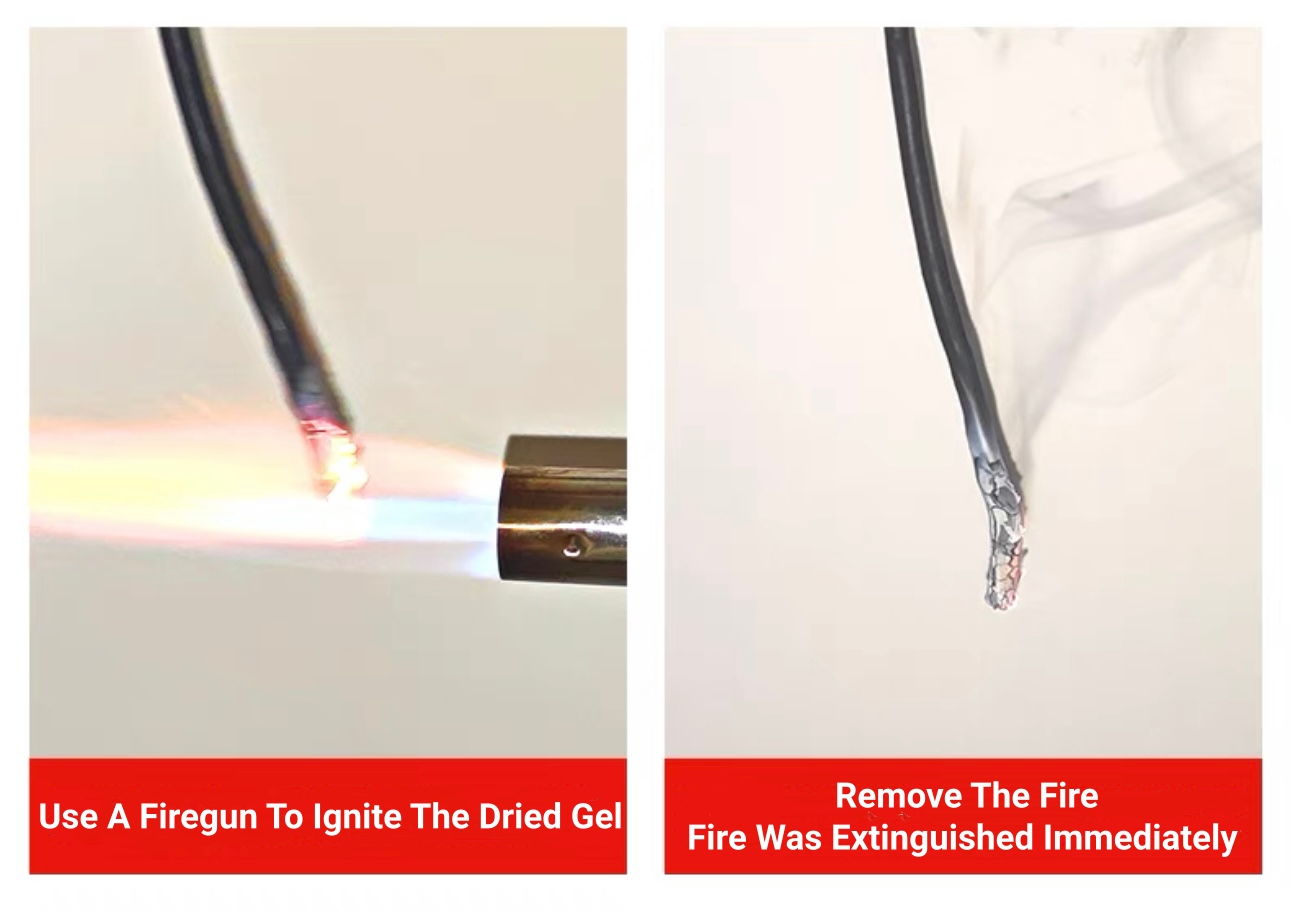

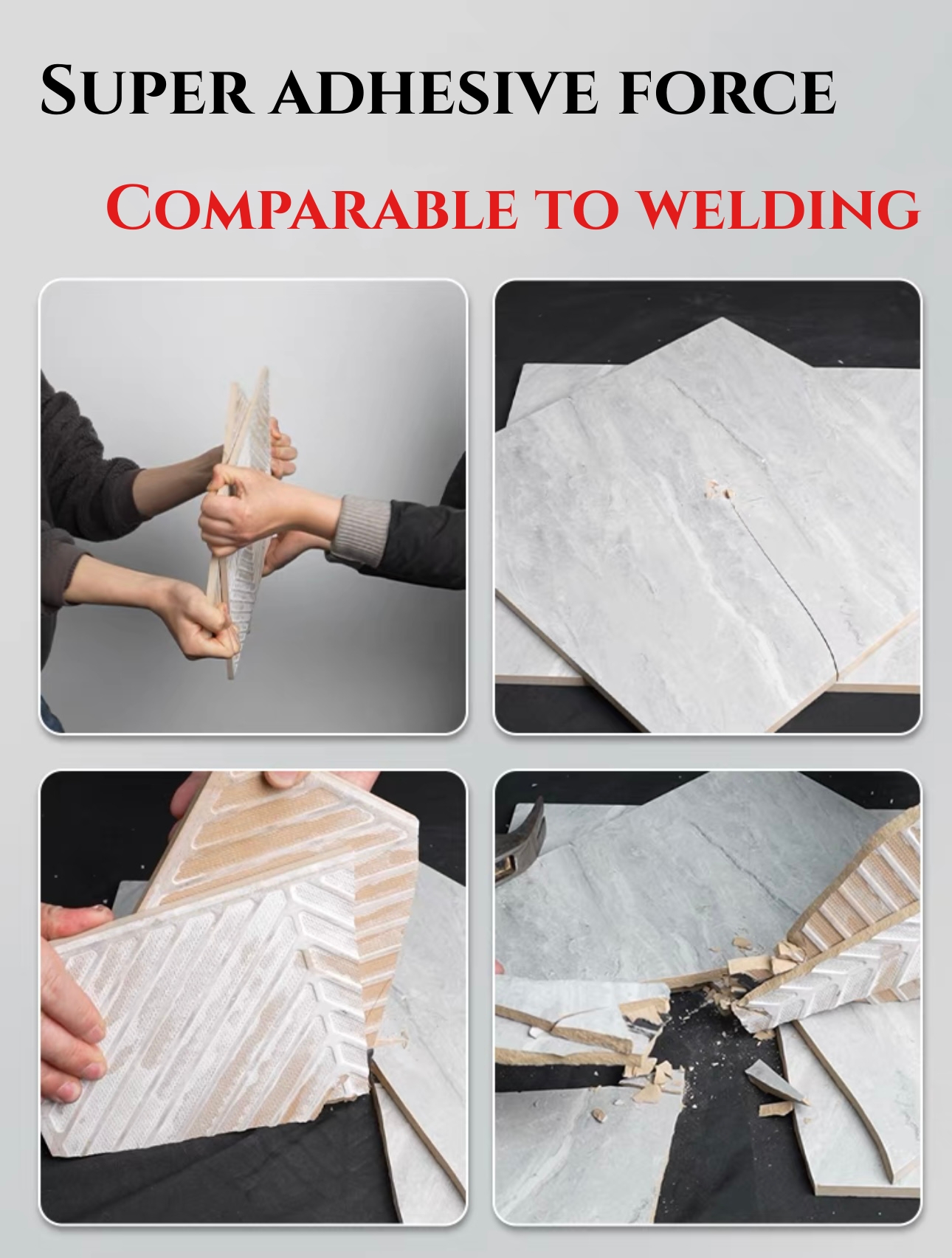

This product is a one-component neutral silicone flame-retardant fireproof adhesive for construction. It adopts advanced technology and formula, and selects the best materials. It has certain elasticity and adhesive sealing properties after being cured by exposure to moisture at room temperature. It has excellent vibration resistance, It is resistant to cracking, high and low temperature, and aging, and has the dual functions of flame retardant and sealing.

FRS-109 Product Parameters

| Application Method | Use with applicators |

| State | Paste |

| Model Number | FRS-106 |

| Product Name | Silicone flame retardant sealant |

| Color | Red; Customized |

| Feature | Fireproof, long service life,flame retardant, environmental protection and pollution-free. |

| Type | silicone sealant |

| Use | ① Bonding and flame retardant sealing of various types of fire doors and windows; ② Flame retardant sealing of each layer of curtain wall project; ③ Waterproof, moisture-proof, decorative and other flame-retardant sealing in public places such as hotels, theaters, etc.; ④Fixing and flame-retardant sealing of electronic and electrical components such as stoves, disinfection cabinets, electric steamers, electric ovens, induction cookers, microwave ovens, etc |

| Shelf Life | 12 months |

| Certificate | GB/T 24267-2006-FV0level |

| Packing | 450g Rigid Packing/ 750g Flexible Packaging/ 200kg Drum /Customized |

| Selling Units | piece |

| Single Package Size | 5.2*5.2*23 cm |

| Single Gross Weight | 0.52 KG |

| MOQ | 1440pieces |

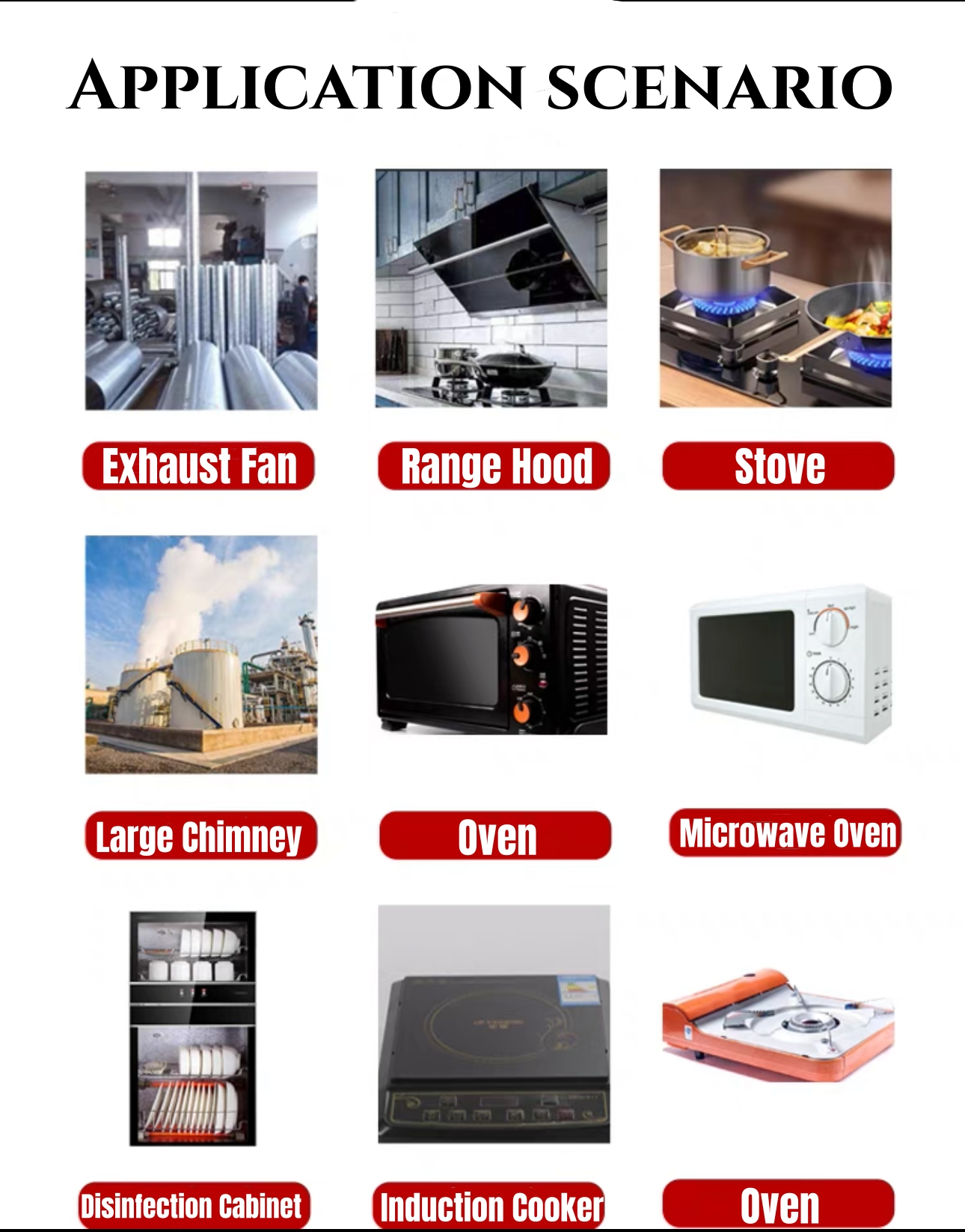

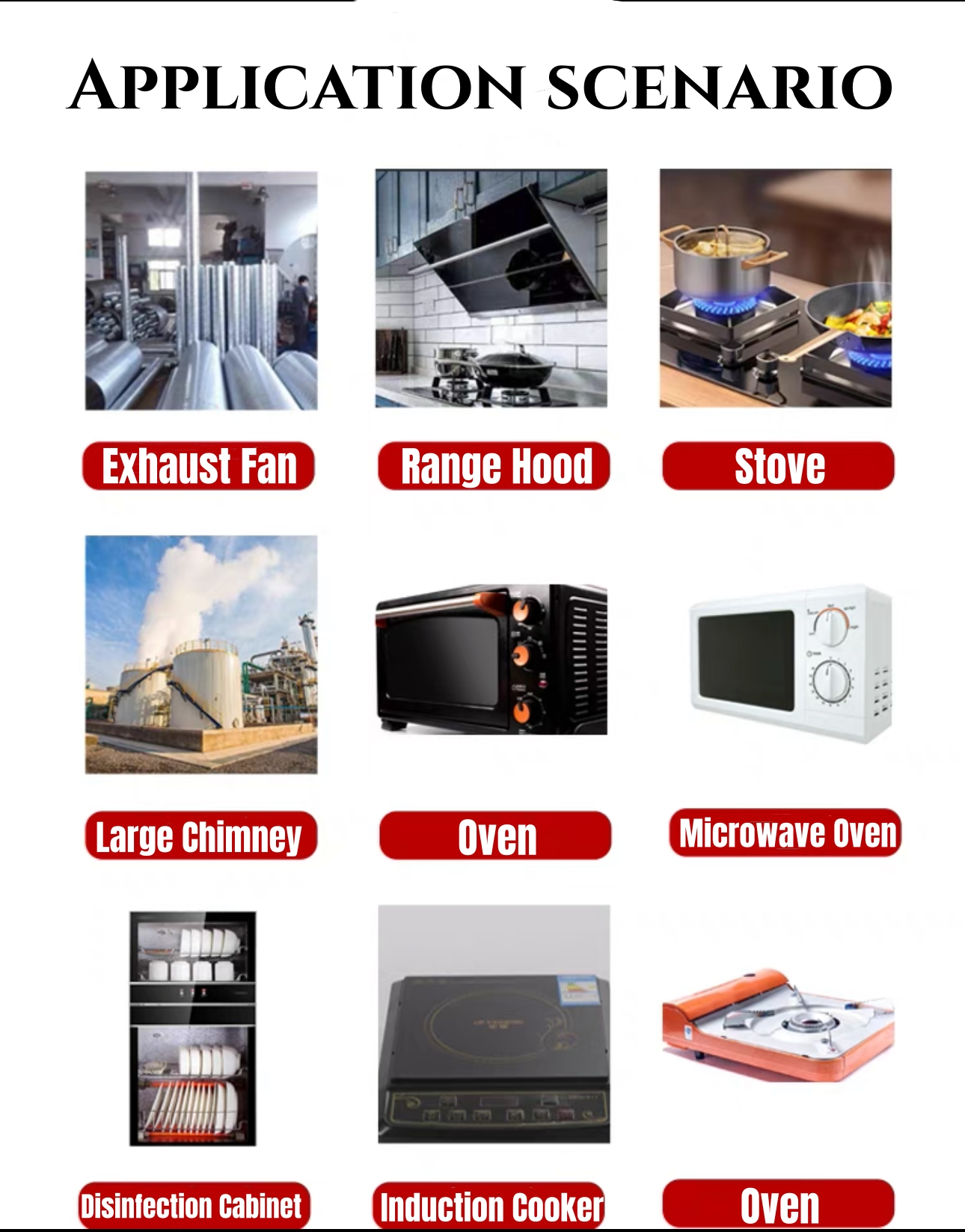

FRS-106 Product Application Scenarios

① Bonding and flame retardant sealing of various types of fire doors and windows;

② Flame retardant sealing of each layer of curtain wall project;

③ Waterproof, moisture-proof, decorative and other flame-retardant sealing in public places such as hotels, theaters, etc.;

④Fixing and flame-retardant sealing of electronic and electrical components such as stoves, disinfection cabinets, electric steamers, electric ovens, induction cookers, microwave ovens, etc

FRS-106 Product User Guide

①Clean the construction surface to ensure it is dry and free of oil and dust;

② Paste protective tape on both sides of the construction. If the joint is too wide, fill the joint with lining material;

③ Cut the mouth of the bottle and install the glue nozzle. Cut the glue nozzle according to the required size and squeeze it out with a glue gun;

④ The sealant squeezing action should be carried out continuously to make the glue evenly squeezed out and move evenly and slowly to ensure that the joint is filled with sealant. It is necessary to prevent the nozzle from moving too fast and causing bubbles or cavities;

⑤ Complete the trimming within 10 minutes after gluing and remove the protective tape;

⑥This product reacts with moisture in the air and solidifies. It dries to the surface in 1 to 3 hours at room temperature and forms a solidified layer on the surface in 1 day. Depending on the contact area with air and bonding depth, it takes 1 to 7 days to cure to achieve the best effect.

FRS-106 Product Details